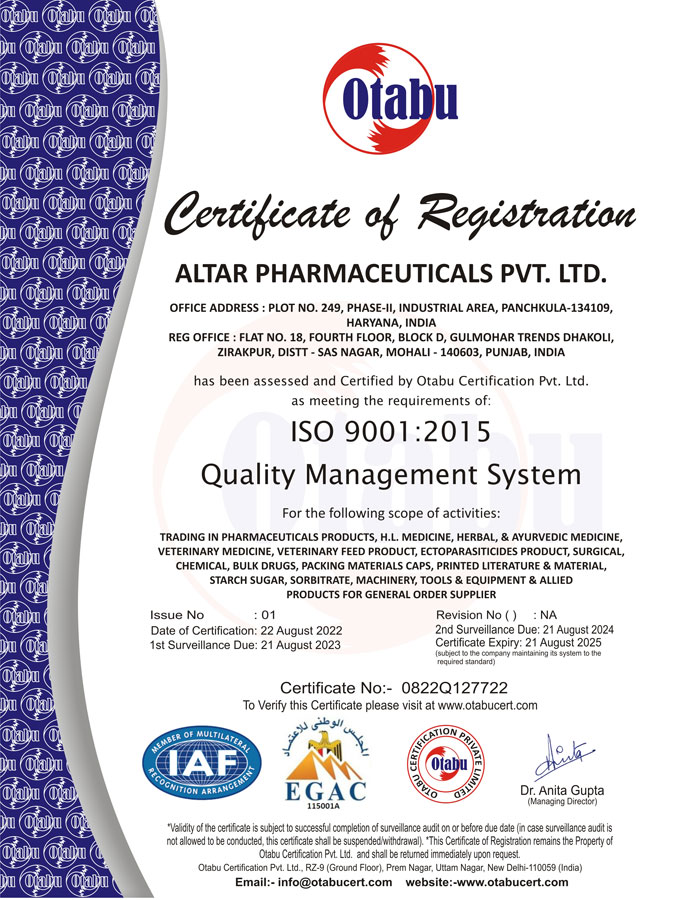

Quality is a foundation on which the company has built its reputation. Altar Pharma (A Pharmaceutical Company) is ISO 9001:2015 certified company, making infinite efforts to meet and exceed current good manufacturing practices (cGMP) norms and continue to invest in our people, process and equipment to ensure that we remain an industry leader.

Altar Pharmaceuticals Pvt. Ltd. is committed to maintain the highest standards of quality, the products meet relevant pharmacopeial standards and statutory requirements. In addition, the company ensures that all the steps involved in design, development and manufacture of a product leads to the intended level of quality performance in the market. This commitment to quality requires us to ensure that our facility is geared up to provide the right environment, our personnel are trained and quality conscious, our packaging provides the requisite security and cosmetic appeal and our products provide complete customer satisfaction.

Manufacturing & supplying excellent quality drugs to consistently meet the needs of esteemed clients and the mankind in general. We manufacture our products in only plant that are cGMP certified and ensuring strict compliance with cGMP guidelines, prevailing national and international standards in accordance with the pharmaceutical industry. Treating health, safety and environmental protection as an integral part of the quality strategy. Enhancing customer satisfaction through continuous improvement in quality management System in conformity with ISO 9001:2015

It is the policy of Altar Pharmaceuticals Pvt. Ltd. to ensure that all products and services offered to our company's customers consistently conform to all applicable regulatory requirements and with the principles and guidelines of current Good Manufacturing Practice (cGMP) to ensure a "fitness for use" expected by our customers' contractual expectations.

Furthermore, it is our policy to ensure that (1) Altar Pharma's facilities and (2) product development, manufacturing and logistics processes that directly affect the quality of the final medicinal product, are identified and controlled to provide a high degree of assurance that each commercial product consistently meets its pre-defined specifications and quality attributes.